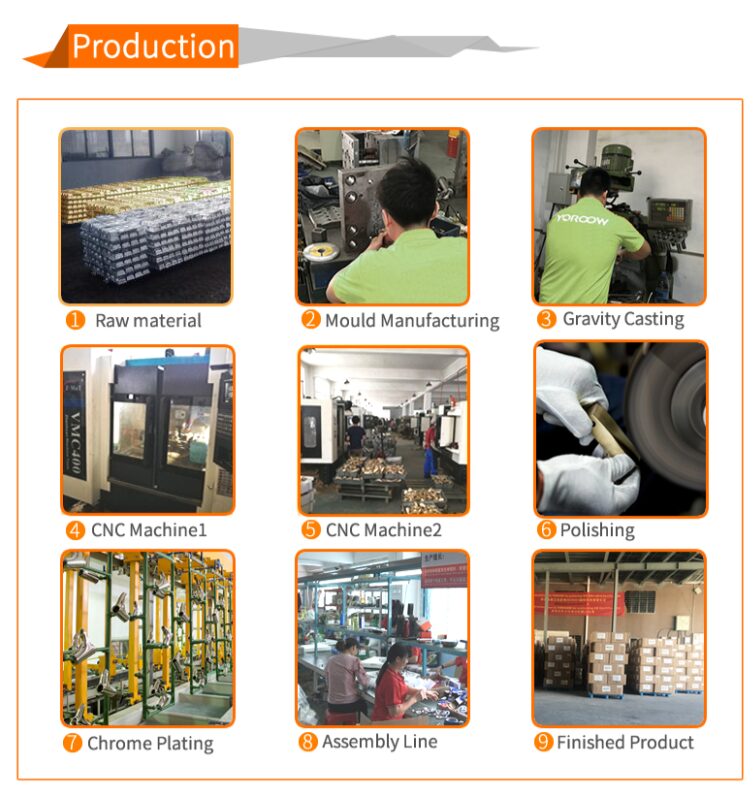

YOROOW faucet factory is committed to the manufacture of high-quality faucets. The entire production process covers multiple key links such as design, mold making, casting, polishing, machining, electroplating, assembly and testing. Each step is strictly controlled to ensure the durability, aesthetics and functional stability of the product,the following is a detailed introduction:

Table of Contents:

Design

Mould Making

Casting

Polishing

Machining

Plating

Assembly

Test

Packaging

Shipping

1️⃣ Product Design and Development

↓

2️⃣ Mold Manufacturing (CNC+EDM)

↓

3️⃣ Gravity/Vacuum Casting (Brass Melting + Pouring + Cooling)

↓

4️⃣ CNC Machining (Drilling + Tapping + Finishing)

↓

5️⃣ Surface Treatment (Electroplating/Matte Black Spraying/Brushing)

↓

6️⃣ Finished Product Assembly (Valve Core + Sealing Ring + Nozzle + Handle)

↓

7️⃣ Quality Inspection (Air tightness + Size + Life Test)

↓

8️⃣ Packaging and Delivery (Customized Packaging + Brand )

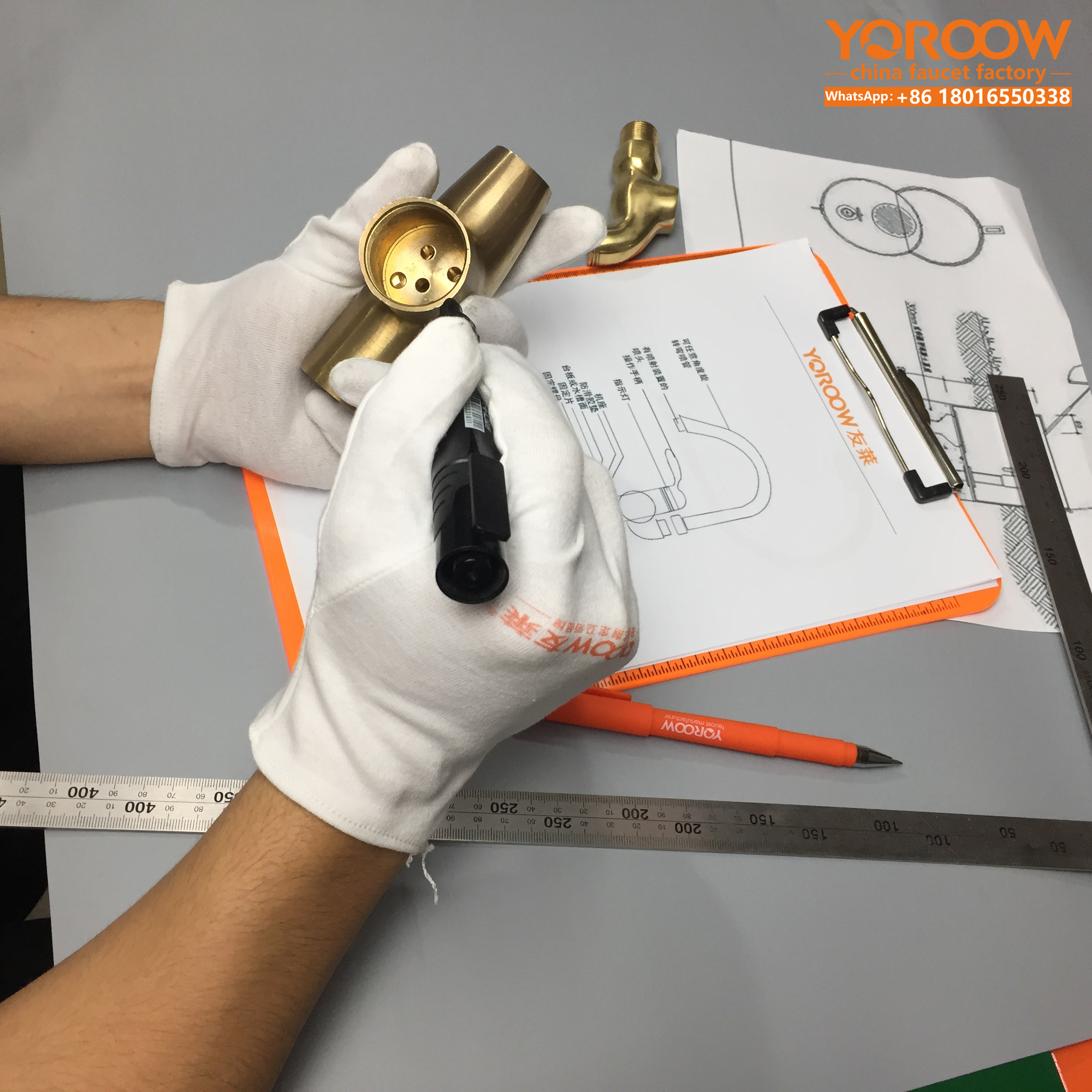

(I) Design: Precise Design Lays The Foundation for Quality

At the YOROOW factory, design is the primary link in the faucet production process , which directly determines the user experience, appearance style and market competitiveness of the product. Our R&D team closely follows the global market trends, integrates ergonomic principles and real user feedback, and creates high-performance faucet solutions that are both beautiful and practical. In particular, in the process of cooperating with Brazilian customers , we have summarized a set of design processes that are adapted to the preferences of the Latin American market:

I. Market Research

YOROOW regularly collects and analyzes consumer data from the South American market every year. In 2024, during our cooperation with a large building materials chain in Sao Paulo, Brazil, we conducted a field survey and found that:

More than 74% of end consumers prefer kitchen faucets with high bends, pull-out functions and corrosion-resistant surface treatments ; nearly 60% of users prefer matte black and electroplated chrome surfaces; and in emerging market cities such as Fortaleza and Belo Horizonte, economical and high-value products have become the main sales force.

In response to the above trends, we developed a pull-out kitchen faucet model 7521B1-071P5-N25L specifically for this customer , which combines the modern shape and multifunctional design preferred by Brazilian users.

Technical Parameters Overview(521B1-071P5-N25L)

| Item | Parameter Description |

| Material | 59A Grade Brass |

| Surface Treatment | Three-layer Electroplating

(Nickel + Chrome / Matt Black) |

| Water Outlet Function | Dual Mode (Bubble + Spray) |

| Pull-out Length | 480mm |

| Working Water Pressure | 0.05-1.0MPa |

| Flow Rate | 7.2L/min (Water-saving Grade A) |

| Valve Core Life | >500,000 Times |

| Adapter Hose Interface | G1/2 |

| Installation Method | Single Hole Basin Installation Quick Connect Structure |

II. Product Modeling

The design team used SolidWorks and AutoCAD for 3D product modeling. Taking 7521B1-071P5-N25L as an example, in order to meet the common medium-sized kitchen layout in Brazil, we optimized the faucet body height to 310mm, set the nozzle pull-out length to 500mm, and the 360° rotatable design is suitable for double-sink washing scenarios to ensure flexibility of use.

III. Simulation Analysis

During the development of 7521B1-071P5-N25L, we used ANSYS CFD fluid simulation tools to dynamically simulate the water flow path. After three rounds of iterations, we finally stabilized the water flow rate at 7.0L/min, reduced the splash rate by 18%, and improved the water-saving efficiency to Class A standards, meeting Brazil’s market orientation for energy-saving and environmentally friendly products.

IV. Structural Optimization

In terms of product structure, we use 59A-grade brass body and ceramic valve core , which have passed 500,000 durability tests to ensure that the product can be used stably for more than 10 years. The installation method combining quick-connect nuts with flexible water inlet pipes also improves terminal installation efficiency by about 35%. In the self-operated stores of Brazilian cooperative customers, the installation satisfaction score reached 4.9 stars (out of 5 stars).

After the design is finalized, YOROOW will quickly start the mold manufacturing process, combining CNC processing and precision casting technology to ensure that the product maintains high consistency and market adaptability from sample to mass production. Our R&D and design teams also continue to communicate with local Brazilian customers, continuously optimize product details based on user feedback, and help customers gain terminal competitive advantages.

(II) Mold Making: High-precision Molds to Ensure Casting Quality

The mold is the most critical foundation in faucet production, which directly determines the appearance, structure accuracy and surface quality of the product. YOROOW factory always puts mold development first, using CNC (computer numerical control) processing, electric spark (EDM) precision discharge technology, heat treatment and polishing technology to ensure that each set of molds is accurate and durable to meet the personalized needs of different markets. For the Brazilian market, our mold development process is as follows:

Mold Design :

Based on the customized 3D product model, combined with the gravity casting process standards, the mold structure is designed. Take the kitchen faucet (model 7521B1-071P5-N25L ) customized by YOROOW for a customer from Sao Paulo in 2024 as an example. The customer hopes that the product has a generous and modern shape, a high water outlet angle, and is suitable for the local kitchen space layout. We designed a single-cavity DC mold and reserved a special structural position at the junction of the handle and the water outlet pipe to facilitate subsequent assembly.

CNC Processing :

During the mold manufacturing process, DMG five-axis CNC numerical control equipment imported from Germany is used to ensure that the accuracy of each mold component is controlled within ±0.005mm. The handle groove area of the 7521B1-071P5-N25L mold reserves a laser engraving position for the customer’s customized LOGO, and local precision milling is performed during the processing process to ensure that the subsequent brand display is clear and three-dimensional.

Heat Treatment :

The mold material is H13 high temperature resistant mold steel, and through vacuum quenching and tempering treatment, its hardness reaches about HRC 50, effectively extending the service life. The mold has completed the production of nearly 22,000 castings in half a year, and still maintains the high precision of the water outlet and thread position.

Grinding and Polishing :

In view of the mirror electroplating process preferred by the Brazilian market, we use multiple rounds of mirror grinding technology in the mold polishing stage, which ultimately reduces the surface roughness Ra value of the casting to within 1.2, greatly reducing the subsequent grinding cost and improving the adhesion of the surface coating.

According to YOROOW’s experience in cooperating with many Brazilian customers, Brazilian users generally prefer kitchen faucets that combine stylish appearance and practical functions , and pay special attention to smooth water flow and water-saving functions. We took these market preferences into consideration at the early stage of mold development to ensure that every casting detail meets customer expectations.

After the mold development is completed, the relevant models will enter the casting production stage, laying a solid foundation for the mass production of high-quality faucets. YOROOW factory provides one-stop faucet OEM/ODM services from mold design to product mass production, and is committed to creating a truly efficient collaborative experience “from design to delivery” for Brazilian and global customers.

(III) Casting: Precision Casting to Ensure The Quality of The Blank

In the YOROOW factory, the casting process is the core link that determines the structural strength and service life of the faucet . In response to the continuous demand of the Brazilian market for high-quality, cost-effective products, we mainly use gravity casting and precision casting to ensure that the castings are dense, pore-free, corrosion-resistant, and adaptable to the hot and humid Brazilian family kitchen faucet and bathroom environment.

Casting Process (Taking Export Model 7521B1-071P5-N25L as an Example):

I. Raw Material Smelting

59A grade brass as the main material according to customer needs . This material is highly accepted in the Brazilian faucet market, especially in coastal cities such as Rio de Janeiro and Sao Paulo, and its corrosion resistance is better than general copper.

During the mass production of 7521B1-071P5-N25L, we use a high-temperature induction furnace to melt brass to about 1120°C, and filter impurities through a special slag remover to keep the purity of the molten metal> 99.98%, ensuring that the castings are free of inclusions and black spots.

II. Pouring

We use gravity casting + vacuum assist system to slowly inject molten metal into the mold to effectively prevent the formation of pores. Taking 7521B1-071P5-N25L as an example, the average wall thickness of the faucet is controlled at 2.8mm, and the casting density reaches 7.9g/cm³. It is strong and pressure-resistant, ensuring that there is no leakage or cracks in the 16kg high-pressure water pressure test.

III. Cooling Molding

After pouring, the casting is cooled naturally for about 30 minutes, and then the air cooling system is used to accelerate the solidification of the outer wall. In an annual order project of a customer in Sao Paulo, we optimized the cooling curve to control the shrinkage rate of the casting to 1.2%, reducing the difficulty of subsequent processing and improving the consistency of the finished product.

IV. Demolding

After cooling, the faucet blank is automatically taken out by hydraulic demoulding equipment, and unqualified parts are screened out by manual first inspection to ensure a yield rate of >96%. According to Brazilian customer feedback, YOROOW castings have a high surface flatness and do not require excessive polishing, which is well received by installers and retail customers.

V. Clean Up

The castings will be sandblasted, polished, pickled and other processes to remove burrs and oxide scale. In the export batches, we have especially strengthened the control of sandblasting uniformity, which has increased the subsequent electroplating adhesion by 12%, laying a solid foundation for the matte black, brushed nickel and gun gray surface treatments popular in the Brazilian market.

The entire casting process provides a structural foundation for subsequent finishing, polishing and electroplating. In the many years of cooperation with Brazilian customers, YOROOW has always won the trust of channel dealers with ” high-quality faucet bodies + cost-effective delivery capabilities “. In 2024, we have cast more than 380,000 faucet bodies for the South American market, and continue to optimize molds and casting parameters to ensure stable delivery and excellent quality.

(IV) Polishing: Fine Grinding to Improve Appearance Quality

In the YOROOW factory, polishing is not only a process to improve the appearance, but also a guarantee of electroplating adhesion . In response to the high requirements of Brazilian consumers for “appearance texture” and “smooth touch”, we have established a dual process covering mechanical polishing + manual finishing .

Polishing Process (Taking the Popular Model 7521B1-071P5-N25L As an Example):

Rough Grinding and Shaping :

Use high-speed grinding wheels to initially shape the blanks and remove gate residues and oxide scale. Through imported grinding equipment, the shell roughness of the 7521B1-071P5-N25L faucet body is reduced to Ra1.6, meeting the subsequent fine polishing standards.

Fine Polishing :

Entering the cloth wheel + polishing wax stage, the technicians perform manual operation. The polishing time of each faucet is controlled at about 9 minutes to ensure that the surface is round and has no dead corners. It is especially suitable for styles with high requirements for matte texture.

Removal of Impurities and Cleaning :

After polishing, all products pass through an ultrasonic cleaning tank to thoroughly remove wax stains and fine dust to prevent affecting the electroplating adhesion rate.

Customer Preference Data Reference:

In a customized project with X Company, a Sao Paulo customer in 2024, the 7521B1-071P5-N25L was well received for its “mirror-grade polishing effect” and “rounded corners”. In its local warehouse evaluation, consumers scored the faucet’s appearance as high as 4.7/5 .

After polishing, the faucet enters the machining stage.

(V) Machining: Precision Machining to Ensure Accurate Installation

In the production process of faucets, machining is the core step to ensure the functionality and assembly accuracy after casting. For the kitchen faucet model 7521B1-071P5-N25L exported to the Brazilian market , we use high-precision CNC equipment such as CNC lathes, automatic drilling machines, CNC tapping machines, and three-coordinate measuring machines (CMM) to ensure that the products meet the strict standards of Brazilian customers for “high adaptability”, “smooth water flow” and “long life”.

7521B1-071P5-N25L Ucet Machining Process Details:

Drilling (Precisely Matching The Interface Standard):

7521B1-071P5-N25L is designed as a dual water inlet structure. In view of the G1/2 standard interface commonly used in Brazil, during the CNC drilling process, the size of the inlet and outlet holes is controlled within an error of ±0.05mm. The diameter of the nozzle outlet hole is 22mm, which ensures stable water pressure and facilitates Brazilian users to directly connect standard hoses and bubblers.

Tapping (To Ensure Tightness and Ease of Installation):

This model of faucet is processed with an automatic tapping system, with a thread depth of 10mm, a tightness of 6H, and 100% leakage-free in on-site testing. In 2024, when cooperating with the Fjia bathroom chain in Paraná, Brazil, a special assessment of thread accuracy was made. The sealing test pass rate of this batch of products was 100%, and a tight connection can be achieved without the use of additional sealing rings.

Inner Cavity Finishing (Optimizing Water Flow Efficiency):

In order to achieve a more efficient water flow experience, the internal water channel of 7521B1-071P5-N25L was corrected and polished three times during the machining stage, and the final inner wall roughness was reduced to Ra0.8. According to internal testing, the water flow rate of this model reached 7.5L/min, and the water flow was stable and concentrated, which is particularly suitable for the frequent use of washing vegetables and tableware in Brazilian kitchens.

Dimension Inspection (To Ensure Correct Assembly):

After processing, all key structural parts are dimensional checked by Hexagon’s three-dimensional coordinate measuring machine. Taking 7521B1-071P5-N25L as an example, the matching accuracy error between its rotating interface and the faucet body is controlled within ±0.02mm, ensuring no jamming or offset during 360° rotation, which is deeply loved by Brazilian customers.

Analysis of Customer Preferences in The Brazilian Market:

About 71% of Brazilian users prefer kitchen faucets with rotatable spray heads and quick-install structures .

Customers generally emphasize that “stable connection and precise interface” are the first criteria for judging product quality.

In 2024, when cooperating with N, a building materials retailer in São Paulo, 7521B1-071P5-N25L successfully replaced the original European brand products due to its high processing precision and strong interface versatility, and received good market feedback.

After machining is completed, the 7521B1-071P5-N25L kitchen faucet will enter the electroplating process to further improve the surface corrosion resistance and appearance texture, providing reliable protection for Brazil’s high temperature and high humidity environment.

(VI) Electroplating: High-standard Surface Treatment to Improve Durability

The electroplating process determines the final color, corrosion resistance and long-term brightness of the faucet. YOROOW has a fully automatic three-layer electroplating production line , combined with a copper + nickel + chromium three-layer composite electroplating solution, to ensure that each faucet has a bright surface, uniform color, and is durable and does not fade.

Electroplating Process (Taking the Brazilian Special Model 7521B1-071P5-N25L as an Example):

Copper Layer Primer :

The thickness is controlled at about 8μm to improve the surface flatness and enhance the adhesion of the subsequent nickel layer.

Nickel Layer Anti-corrosion :

Environmentally friendly lead-free nickel solution is used, and the electroplating thickness reaches 15μm, ensuring long-term corrosion resistance even in the high humidity environment of the Brazilian coastal area.

Chromium Layer Sealing Protection :

Electroplating 0.3-0.5μm high-brightness chromium layer provides the faucet with a mirror effect and extra hardness. After a neutral salt spray test, it can last for ≥96 hours without blistering or corrosion , which is higher than the Brazilian import standard.

Surface Color Customization (Optional):

To meet the needs of South American users for personalized decoration, YOROOW supports a variety of surface treatments:

Matte Black

Brushed Nickel

Gunmetal

Gold Look

Actual Customer Feedback Cases:

In the first half of 2024, we customized 12,000 matte black kitchen faucets for a large home improvement brand in Curitiba. After half a year of market tracking, about 73% of end consumers said that “surface treatment is one of the main reasons why they chose this product.”

(VII) Assembly: Precision Assembly to Ensure Stable Functions

In the YOROOW factory, assembly is not only a mechanical operation, but also a delicate project directly linked to user experience. For the 7521B1-071P5-N25L kitchen faucet exported to the Brazilian market , we have formulated a strict standard operating procedure, covering all key links such as valve core, seals, spouts and control components, to ensure that the faucet still maintains sensitive operation, no leakage, uniform water flow and other performance advantages during long-term use.

7521B1-071P5-N25L Assembly Process Record (Brazilian Customer Customized Standard):

Valve Core Installation: Smooth Feel, Durable for Over 10 Years.

Ceramic valve core (Φ35mm) is embedded in the faucet body by an automatic assembly system, and its rotation angle and opening and closing smoothness are manually reviewed. In the delivery project of customer M in Minas State, Brazil in 2024, this model has been tested for 500,000 times of opening and closing life, and still maintains a smooth opening and closing state, which is widely praised by customers.

Sealing Installation: Double Sealing Structure, Effective Leakage Prevention.

7521B1-071P5-N25L is equipped with a three-layer structure sealing ring (EPDM material + silicone waterproof ring + stainless steel gasket), which is combined with manual and automatic press installation to ensure a tightness of > 95%. Customer feedback from the Sao Paulo building materials channel pointed out: “Even under high water pressure conditions, there has never been a dripping problem for a long time.”

Spout Assembly: The Bubbler Stabilizes The Pressure and Controls The Flow, and The Water Flows Gently.

This faucet uses a detachable ABS bubbler. During the assembly process, the internal filter layer is firmly combined with the outer cover to prevent loosening after long-term use. The measured water flow rate is 7.5L/min, and the bubble mixing rate is as high as 28%, which effectively reduces splashing. It is especially suitable for the deep tank design and hot water mixing water use scenarios in Brazilian kitchens.

Installation of Handle and Control Components: Smooth Rebound, Sensitive Regulation.

Zinc alloy handle + stainless steel shaft structure is adopted. After installation, each batch must pass the “hand feel rebound force test” and “temperature adjustment smoothness evaluation”. 7521B1-071P5-N25L has hot and cold markings and is intuitive to operate. Brazilian customers generally believe that “even with wet hands, the water temperature can be accurately controlled.”

Case Study of Assembly Detail Optimization in The Brazilian Market:

In the cooperation with the C kitchen brand in Rio Grande do Sul, Brazil in 2024, the customer specifically requested to enhance the rebound smoothness of the sprinkler hose after stretching. During the assembly stage, we added a locking device of the anti-entanglement gravity hammer to increase the automatic resetting efficiency of the sprinkler to 94%.

Brazilian consumers prefer kitchen faucets with “adjustable water flow + high arc design”, and the 7521B1-071P5-N25L, with its 360° rotation and extendable design, coupled with a smooth assembly structure, has a repeat purchase rate of over 27% in the South American market.

After 7521B1-071P5-N25L is assembled, it will enter a strict finished product testing and appearance quality inspection process to ensure that each faucet meets YOROOW export standards and Brazilian market usage expectations before leaving the factory.

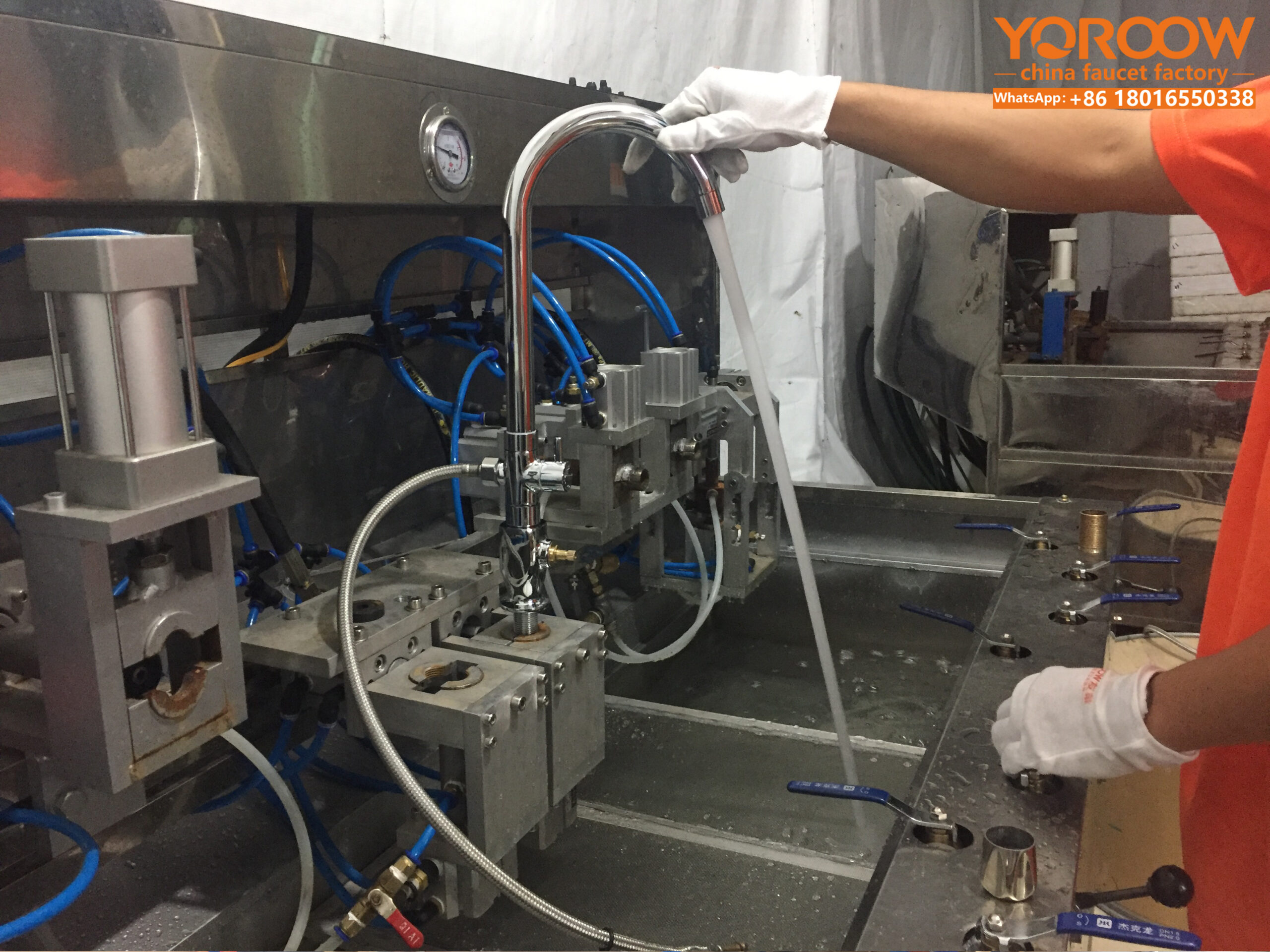

(VIII) Testing: Strict Testing to Ensure Quality

YOROOW always adheres to the principle of “zero defect factory“. 7521B1-071P5-N25L kitchen faucet must pass 6 professional tests before leaving the factory to ensure that it can still operate stably under high temperature, high pressure and high frequency use environment. The quality inspection process is as follows:

Water Pressure Test (Leak Test) :

Connect the finished faucet to the test equipment, apply 84 Bar), maintain pressure for more than 15 minutes, and confirm that there is no water seepage or leakage.

Among the first batch of 7521B1-071P5-N25L products shipped to Brazil in 2024, the inspection pass rate reached 99.6%, and the customer said that “it can be used after installation without rework.”

Opening and Closing Life Test :

500,000 opening and closing cycle simulations are performed through automatic testing equipment to ensure that the valve core and control parts will not loosen or get stuck due to long-term use.

Appearance and surface treatment inspection :

Quality inspectors conduct visual and tactile inspections to ensure that the electroplating layer is free of bubbles, scratches, and discoloration. For the brushed black style, we have enhanced the anti-fingerprint coating according to the preferences of Brazilian customers to improve the overall aesthetics and durability.

Functional Test (Bubbler, Water Splash Control) :

water connection test to check whether the water is evenly discharged, whether there are bubbles, splashes or noise. 7521B1-071P5-N25L is equipped with a double-layer bubbler structure, which can control the water discharge noise within 45dB in the experiment.

(IX) Professional Packaging: Shipped Thousands of Miles Away, The Appearance is as Good as New

YOROOW provides localized packaging services for different markets. In view of the long transportation cycle and high humidity environment in Brazil, the packaging solution of 7521B1-071P5-N25L has been specially customized:

Moisture-proof Design :

Each faucet is sealed with a moisture-proof film on the outside, and is equipped with a desiccant and a PE anti-scratch cover to prevent the electroplated surface from corrosion or oxidation due to moisture.

Customized Color Boxes and Brand Labels :

support printing Portuguese instructions and customer brand LOGO. In 2024, the customized series of JH Company, a customer in Belo Horizonte, Brazil, uses green and environmentally friendly paper boxes, and prints product barcodes and installation steps on the side of the packaging to facilitate channel distribution.

Anti-collision Structure :

The inner lining adopts EPE customized foam bracket, and the mold is specially made for the structure of 7521B1-071P5-N25L pull-out faucet, so that it is stable and will not move during long-distance transportation, and the anti-fall and compressive strength is increased by 37%.

(X) Shipping Service: Fast Delivery, On-time Delivery

7521B1-071P5-N25L shipments adopt the “full-process logistics coordination + multiple rounds of confirmation before delivery” system to ensure customers have no worries about receiving the goods:

Triple-check The Delivery List :

Before each batch is shipped, the sales, warehouse and loading managers will cross-check the quantity and specifications.

Meet Brazil’s Customs Clearance Requirements :

All export documents such as packing lists, invoices and certificates of origin are available in Portuguese to facilitate customs clearance for customers.

Designated Logistics Partner :

YOROOW cooperates with many customs clearance agents and port warehouses in Brazil, such as the local delivery company in Santos Port, to achieve one-stop service from port to door.

A batch of 7521B1-071P5-N25L orders for delivery in July 2024 were loaded from Fujian to Sao Paulo, Brazil, and the entire transportation time was only 28 days. The customer commented that “the packaging was professional and the products were intact.”